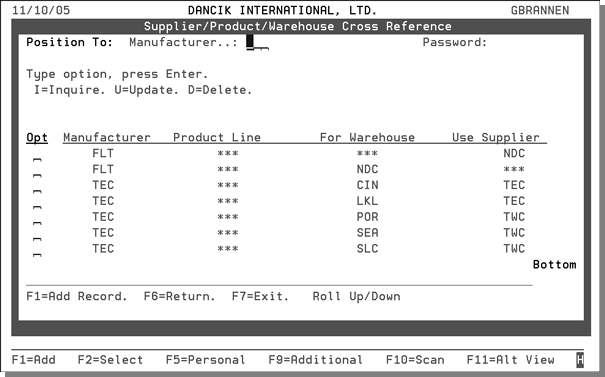

Supplier/Product/Warehouse Table - FIL 45

The Item File allows for entry of a Usual Supplier which is used in the following applications:

- Auto-Generation of Purchase Orders

- Some reports, when the Usual Supplier field is selected as a sort.

When material is ordered, depending upon the warehouse that is ordering, the Usual Supplier may NOT be the correct supplier for that warehouse to order from. On manually written PO's this is not a problem - because the user inputs the appropriate supplier on the PO header. However, the Auto-PO-Generation process relies on the Usual Supplier field.

The Supplier/Product/Warehouse Cross Reference table enables the auto-generation of purchase orders by selecting the correct supplier, based upon the ordering warehouse.

This table can handle the following purchasing scenarios:

- Branches of your business ordering the same product from different suppliers, based upon geography. For example, branch NYC orders product 123 from supplier ABC, but branch LOS orders product 123 from supplier XYZ.

- Branches of your business ordering the same product from different branches of the same supÂplier, based upon geography. For example, branch NYC orders product 456 from supplier AB1, while branch LOS orders the same product from supplier AB2.

This table is accessed via option 45 on the File Maintenance Menu (FIL).

|

Field |

Description |

|

Manufacturer |

The manufacturer of the items being ordered. |

|

Product Line |

The product line will normally be *** for all, but it could be used in situations where one or more product lines need to be routed to a special supplier code. |

|

For Warehouse |

The warehouse that is ordering the material. |

|

Use Supplier |

This entry represents the plant or third party where the product originates from. *** represents the usual supplier as defined in the Item File. |

Using the information shown above, the table is processed within the Auto-Generation process as follows:

- The first entry causes all FLT purchase orders for any warehouses to use supplier code NDC.

- The second entry causes all FLT purchase orders for warehouse NDC to use the usual supplier. This second entry also alters the meaning of the first entry to be for all warehouses except NDC.

- The TEC manufacturer entries allow for the supplier to depend on which warehouse the order is for.

- When an Auto-PO is about to be created, the program reads the table in the following sequence:

- Check for that Mfgr + Prodline + Warehouse in the table. If found, use the supplier as indicated in the Use Supplier column. If not found, continue search.

- Check for that Mfgr + Prodline + *** in the table. If found, use the supplier as indicated in the Use Supplier column. If not found, continue search.

- Check for that Mfgr + *** + Warehouse in the table. If found, use the supplier as indicated in the Use Supplier column. If not found, continue search.

- Check for that Mfgr + *** + *** in the table. If found, use the supplier as indicated in the Use Supplier column. If not found, continue search.

- If no table entries are found, use the Usual Supplier Code in the Item File.

- If a table entry is found, but the supplier is ***, use the Usual Supplier Code in the Item File.

Creating a New Table

- To create a new table, press F1.

- Enter the manufacturer, product line, warehouse, and the supplier to order from. Keep in mind that by entering *** in the Product Line and Warehouse fields, you are selecting all the product lines, all the warehouses. However, *** in the Supplier field signifies that you want to use the usual supplier as designated in the Item File.